The motor lead wire is a cable that links an auto’s motor and battery. Its primary features include incredible resilience against high temperatures and exposure to substances like oil and varnish. Below, find out deeper insights about the motor lead wire.

What is a Motor Lead Wire?

It is the cable transmitting power from the car’s battery to the motor system. Although these wires differ from car to car, they share similar properties such as:

- Excellent corrosion resistance

- Capacity to withstand extreme heat

- Ability to withstand the electric motor vibration

- Good insulation

- Resistance to chemical attack and agents like varnish and oil

What are the regulations for motor lead wires?

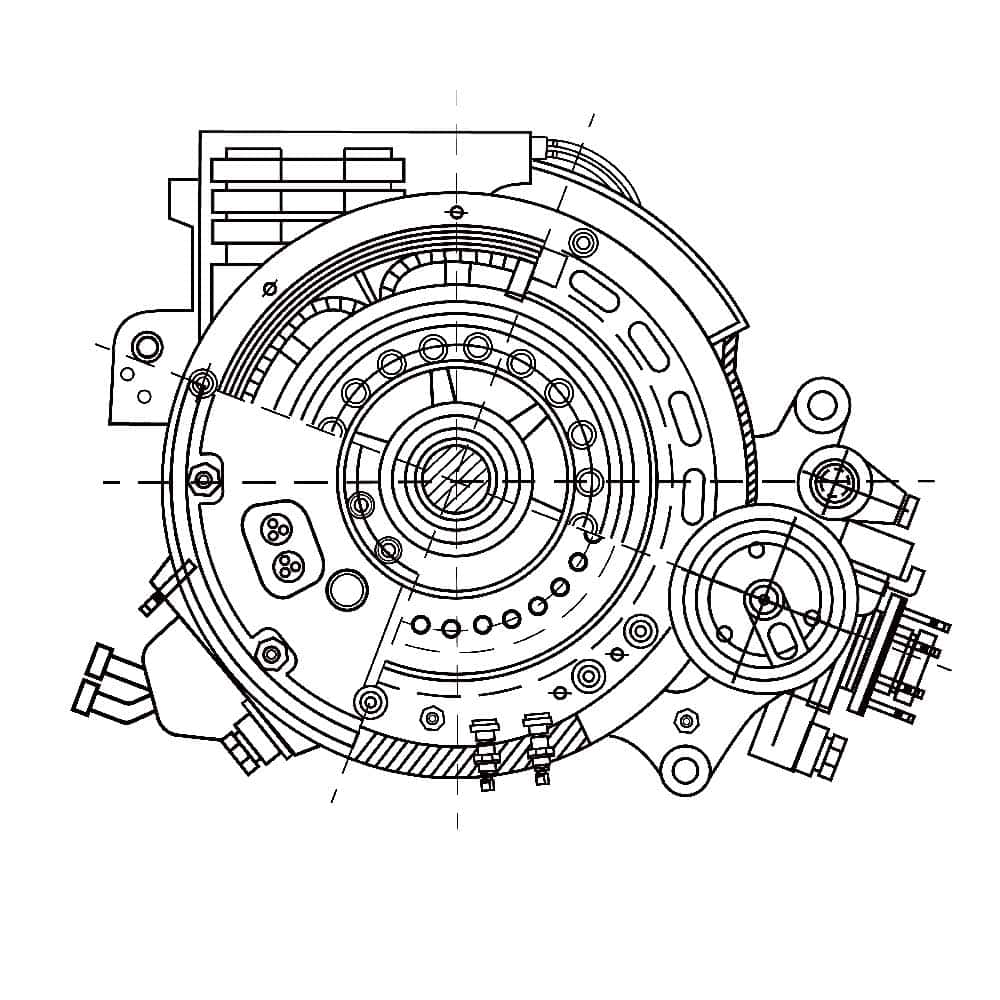

A Car’s Electric Motor

Motor lead wire specifications are under the GB14711 regulations. GB14711 is a standard that governs their safety performance, and it’s internationally accepted. The main rules under this standard are as follows:

Primary Regulations

- If the motor features a power cord, it should also have a lead cable, usually extending from the motor base, to facilitate connection. In addition, it must also feature a plug to allow a link up to a power line when necessary.

- The cord and plugs above must be top-grade and compliant with the industry standards. Hence, they should match industrial standards like corrosion resistance, insulation, and conductor quality. They should also feature the standard dimensions to ensure compatibility with other auto parts.

Grounding Requirements

- Under all circumstances, the wires must always feature a grounding conductor. The only exception is in scenarios where grounding is not necessary. In addition, it is a prerequisite to have unique color codes to distinguish the grounding conductor from the others.

- Furthermore, the grounding wire must meet the grade for earthing purposes regarding cross-sectional area and diameter. It is important to ensure the effectiveness of the grounding work.

Voltage Level Requirements

A Car’s Alternator Motor Parts.

The lead wire must withstand the voltage passing through it. Therefore, it should have a higher rated voltage than the optimal working voltage of the motor.

Moreover, there is also a current requirement that is subject to either of the two conditions. First, it should match the use factor of the load current. Alternatively, it should equal 125% of the full load-rated current.

The one that gives the highest current should be used to determine the wire’s adherence to the current rating.

Protection for the Lead Wire

A thick cable with a plastic cover.

The lead wire should have a protective insulation cover to shield it from the electric motor. In addition, it should feature a clamping device on its ends to prevent tension exerted on it from affecting the conducting wire.

Moreover, the manufacturer of such cables should design them so that they cannot retract into the motor.

The insulation highlighted above mustn’t be a conductor. But if metal is used for insulation purposes, it should be laced with an insulator. This precaution is key in shielding the lead wire from grounding damage.

Line Space Requirements

The lead wire should be easily accessible via the incoming hole to ensure the insulation cover remains intact.

Junction Box Wiring Requirements

A Typical Electrical Junction Box.

This requirement applies to the motor terminal box. The lead cable requires at least 150 millimeters of free length to allow easy connections. Unfortunately, this condition is not a priority in motor production.

Hence, it is highly likely to find wires of a lower length.

What are the motor lead ratings?

An electrical motor drawing.

The table below provides the motor lead wire ratings. These figures are per the Institute of Electrical and Electronics Engineers (IEEE) and UL1446 motor standards.

| Motor Lead Class | Type of Insulation System | Minimum Wire Temperature (in degrees Celsius) |

| B | 130C | 90 |

| F | 155C | 125 |

| H | 180C | 150 |

| R | 220C | 200 |

How do you connect motor leads?

Delta Star Configuration.

When dealing with three-phase motors, it is important to understand that they feature six connection terminals. It translates to six different coils, with each phase featuring two. So, how does this affect the coil’s makeup?

There are two types of motor leads:

- Wyde Configuration

- Delta Configuration

These configurations relate to how the motor coils connect. In addition, it is noteworthy that these motors function in either high- or low-voltage modes. The type of mode depends on whether the motors are in parallel or in series with each other.

When they connect in parallel, that is a low voltage mode. It means that the lower supply voltage is equally distributed amongst the coils. On the flip side, when they are in series, this creates the high voltage mode.

Hence, the high supply voltage is equally distributed amongst the coils in the latter mode.

Conclusion

Understanding the functioning of the motor lead wire is key for any mechanic and even vehicle owner.

In summary, we’ve highlighted the primary regulations governing the quality of the motor lead wire, listed the motor lead ratings, and explained what governs the motor lead connection.